Maybe I should have paid more attention in that lecture when Ron said it was the only wood he was allergic to. Maybe I should have done a little bit of research before I bought it. Maybe I should have noticed all those websites that list it as an irritant that causes nausea, headaches, and has nervous system effects. Maybe thats why all of that 8/4 makore was on sale.

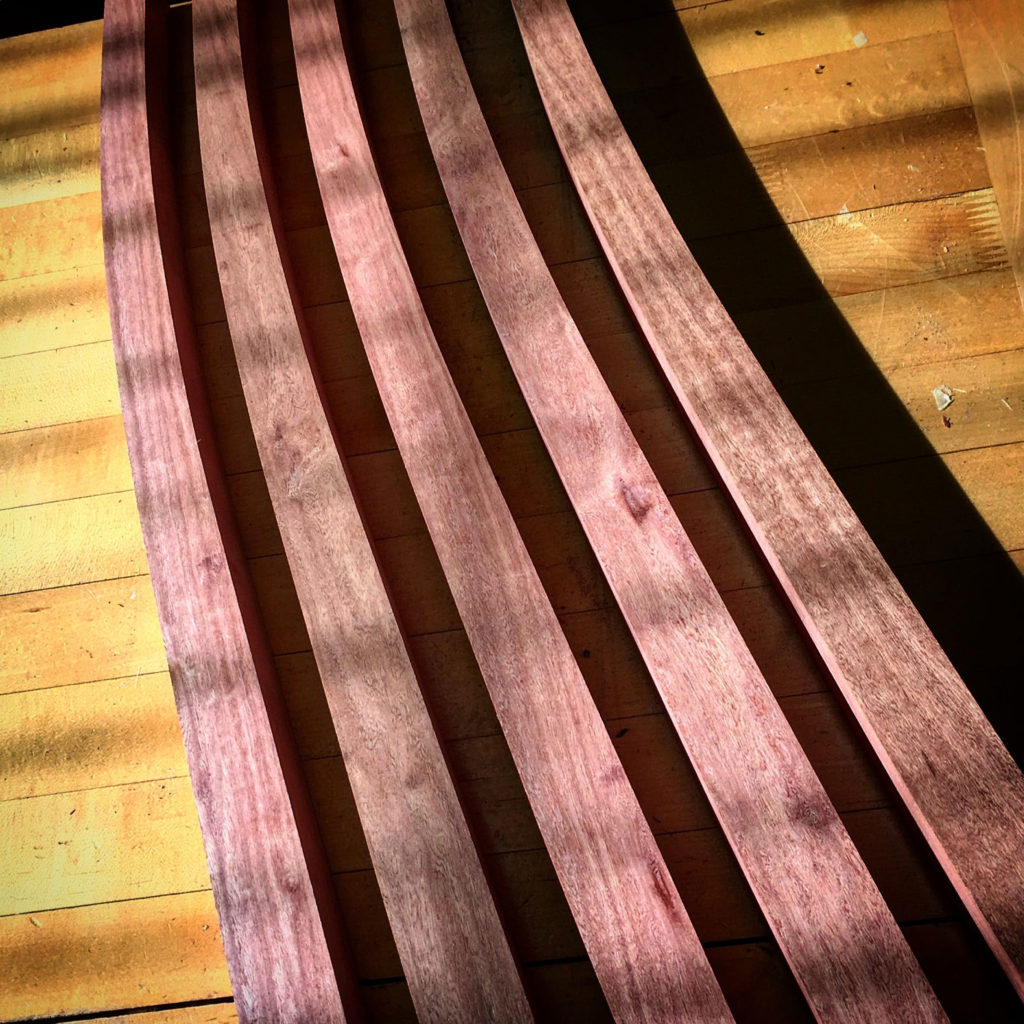

But meh, stunning and planes so smoothly, so there ya go. This was a two stage project, a round veneered top and a solid wood base. We started with a week long intro to commercial veneer, taught by Adrian Ferrazzutti. His best advice when choosing and matching veneer was to avoid making monsters or genitalia. It is now a constant concern of mine.

We began with some simple patterns to get a feel for the material, the glue process, and the vacuum pressing, before moving on to our table tops.

Getting every feature to line up across twelve pieces is an exercise in futility after a while.

But with a lot of glue, veneer tape, and some string inlay, no one can tell.

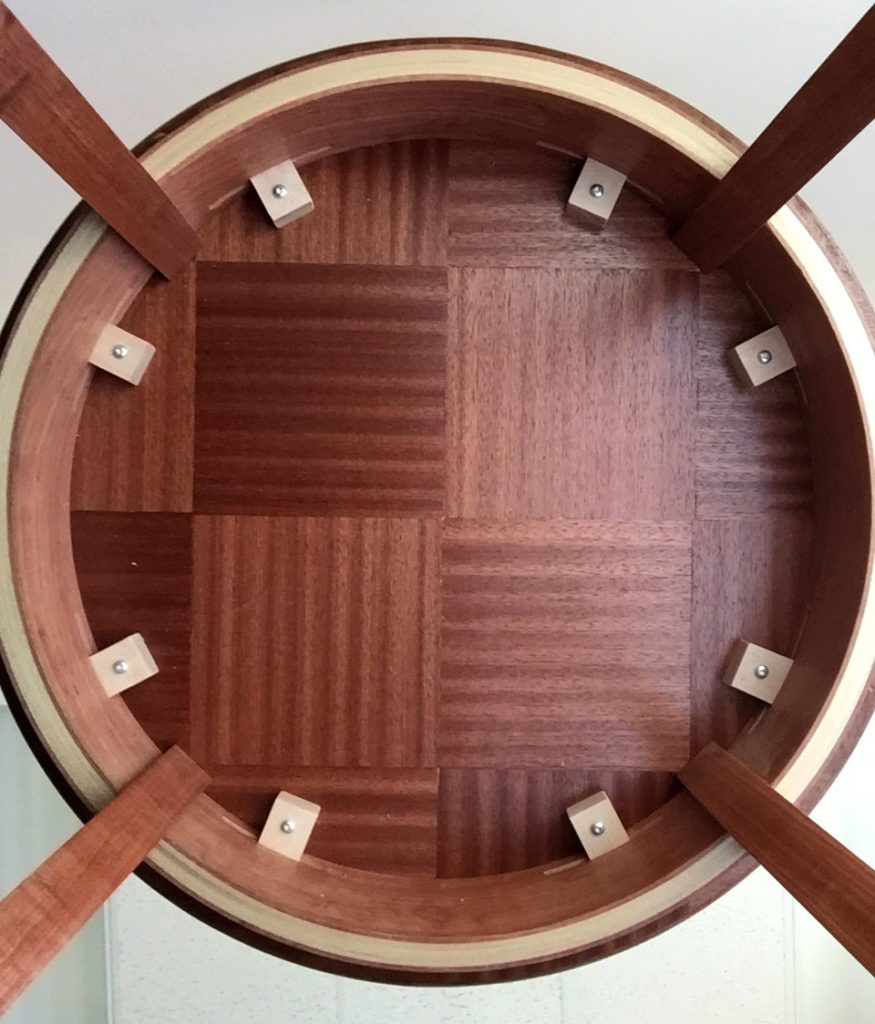

Then came the poison wood.

The leg profiles were shaped with jigs and a router, while the taper from the apron down to the feet was done by hand. The school has very good natural lighting in the afternoon.

Then we got to bend things.

I cut strips of makore, the same way you would cut shop sawn veneers, sandwiched strips of poplar between them (to make the bending a bit easier), them get ready for the clamping. Thanks to the military men in the class, we had a masterful system of efficiency, glue, and brute force. One by one, we laid out our six pieces, slopped them with glue, then slid them into the bending jig. The clamping method was a ratchet strap, the size used to keep King Kong in his cage and hold airplanes together. Three people had to hold the jig in place, while others cranked the strap, and others held the workbench to the ground. Everyone wanted just one more click, one more bead of glue squeezed out.

Then everything gets mortised, scraped, and ready for another multi-part glue up.

Now I get to put this, nearly finished, beautiful piece of furniture on a router table to cut a bunch of holes in it.

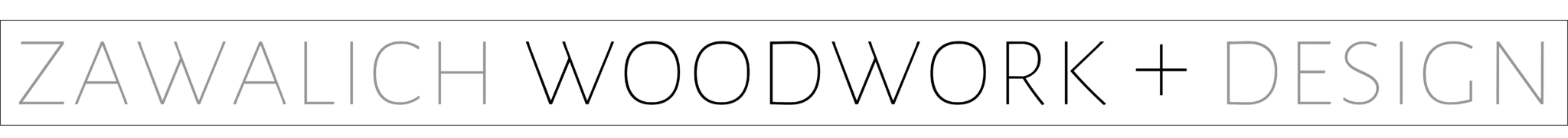

But at least the top stays on. The underside of the top was unnecessarily veneered in mahogany, which no one will ever see.

Empty offices work well for photo shoots.